Effective project management is crucial for the success of any endeavor. Without clear communication, meticulous planning, and strategic implementation, projects can quickly veer off course, leading to delays, budget overruns, and dissatisfied stakeholders. That’s where Albanese Solutions comes in. With their comprehensive project management review and a team of experienced consultants and engineers, they offer cost-effective services that ensure projects are delivered on time and within budget. In this blog, we will delve into the various aspects of Albanese Solutions’ project management services, their areas of expertise, and how their qualified team guarantees successful project outcomes.

Project Management Review:

Enhancing Clarity and Communication Albanese Solutions understands the importance of clear project scope and intentions. By conducting a thorough project management review, they establish effective communication channels to align all stakeholders and ensure everyone is on the same page. This review process sets the stage for successful project implementation, including the development of detailed project schedules, task assignments, update frequencies, tracking metrics, and more. With a focus on communication, Albanese Solutions minimizes misunderstandings and enhances collaboration throughout the project lifecycle.

Cost-Effective Approach:

Leveraging Years of Experience With years of diverse project management experience, Albanese Solutions offers cost-effective services that leverage their extensive knowledge and expertise. They have honed their skills in pulling ahead, working in parallel, and identifying key success indicators while being prepared for potential obstacles. Their long-sighted approach means they proactively anticipate challenges, staying vigilant in monitoring the project’s progress. Rather than relying on luck, they create their own good fortune by paying attention to detail and maintaining a meticulous approach to project management.

Expansive Service Offerings:

From Construction to New Product Development Albanese Solutions caters to a wide range of industries and project types. Their expertise covers areas such as capital projects, construction projects, new factory projects, new process and equipment installations, manufacturing shutdowns, LEAN initiatives, EHS projects, operations initiatives, GMP implementations, EHS training and upgrades, loss time reduction initiatives, Six Sigma initiatives, and new product development. Regardless of the project’s complexity or industry, Albanese Solutions has the experience to manage it effectively.

Hands-On Approach:

Engaging Stakeholders and Ensuring Success Albanese Solutions adopts a hands-on approach to project management. They understand the importance of stakeholder engagement and the concerns of the teams involved. Through frequent touch points, including meetings, interviews, collaborative work tasks, and formal update reports, they foster robust communication channels. By actively involving stakeholders and considering their concerns, Albanese Solutions ensures that projects stay on track and that all voices are heard throughout the process.

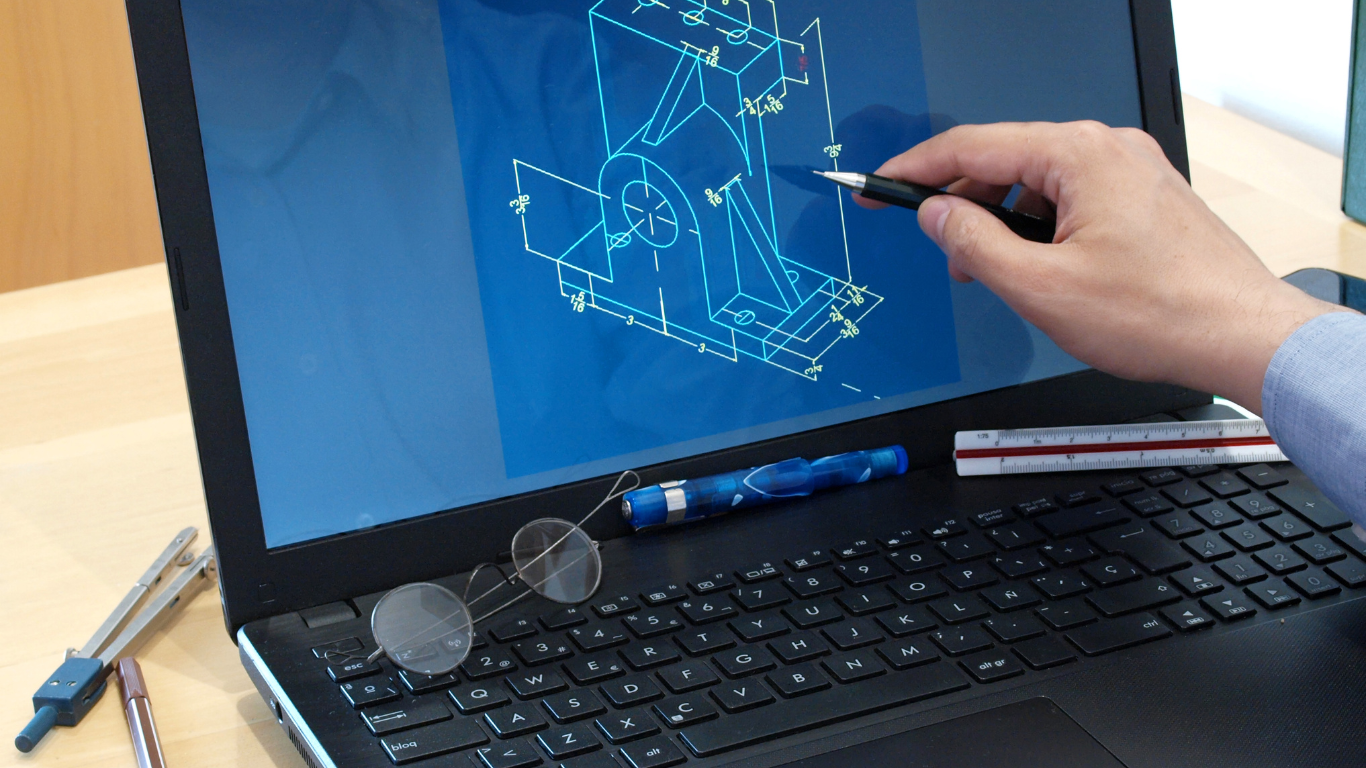

Qualified Consultants and Engineers:

A Winning Team Albanese Solutions takes pride in their team of experienced consultants and engineers. With a commitment to delivering results, they establish clear lines of command and responsibility. By emphasizing mutual accountability and a team-oriented approach, they create an environment where success is achieved together. When you work with Albanese Solutions, their team becomes your team, striving for victory side by side.

Albanese Solutions is the partner you need for effective project management. With their project management review, they lay the foundation for clear communication and successful project implementation. Their cost-effective services, extensive experience, and hands-on approach ensure that projects are delivered on time and within budget. By engaging stakeholders, considering their concerns, and fostering a collaborative environment, Albanese Solutions guarantees project success. Reach out to Albanese Solutions today and embark on your journey towards project excellence.